Description

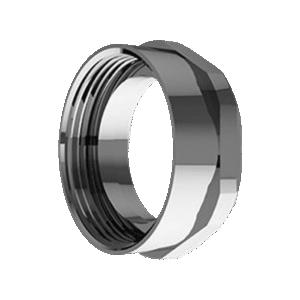

The Loctite 680 retaining compound is a high-performance anaerobic adhesive formulated to bond cylindrical metal assemblies with zero clearance. This green, high-strength compound fills the microscopic gaps between press-fit parts, eliminating movement, fretting, and wear in critical components. Ideal for applications where high load transmission and vibration resistance are required.

Packaged in a convenient 50 ml bottle, it offers precision application for both repair and production environments.

⚙️ Technical Specifications

-

Brand: LOCTITE

-

Model: 680

-

Size: 50 ml

-

Color: Green

-

Type: Retaining compound (anaerobic)

-

Strength: High

-

Viscosity: Medium (150 – 300 mPa·s)

-

Cure Time (Fixture): ~10 minutes on steel

-

Full Cure Time: 24 hours

-

Temperature Resistance: -65°F to 300°F (-55°C to 150°C)

-

Recommended Gap: Up to 0.015″ (0.38 mm)

🧰 Common Applications

-

Press-fit shafts and housings

-

Bearings, bushings, and sleeves

-

Cylindrical parts in motors and gearboxes

-

Retaining rotors on shafts

-

Bonding pulleys, gears, and spindles

-

Mechanical assemblies under vibration or torque

The Loctite 680 retaining compound ensures reliable long-term retention in high-stress, high-speed applications.

💡 Key Benefits

-

High-strength bonding for cylindrical components

-

Zero-movement: Prevents loosening, backlash, and micro-movement

-

Oil-tolerant: Cures even on slightly contaminated surfaces

-

Fast fixture time: Minimizes production delays

-

Seals against corrosion and leakage

-

Temperature and chemical resistant for tough conditions

🛠 How to Use Loctite 680

-

Clean and degrease surfaces thoroughly using Loctite SF 7063 or SF 7070.

-

Apply a continuous bead of Loctite 680 retaining compound around the shaft or inside the housing.

-

Assemble parts with a rotating motion.

-

Fixture time is ~10 minutes; full strength achieved in 24 hours.

-

For disassembly, apply heat (>250°C) and use mechanical force.

Tip: For even faster curing, use with Loctite SF 7471 or SF 7649 activators on inactive metals.

🔍 Compatibility & Substrates

-

Compatible with steel, aluminum, stainless steel, brass, and other metals

-

Performs well even on oily or unprepared surfaces

-

Best suited for close-fitting cylindrical parts with minimal clearance

🏆 Why Choose Loctite?

Trusted by professionals worldwide, LOCTITE retaining compounds are used in OEM, maintenance, and repair operations across industries. The Loctite 680 is a proven solution for press-fit assemblies and components that must not fail—keeping machinery efficient, precise, and durable.

Reviews

There are no reviews yet.