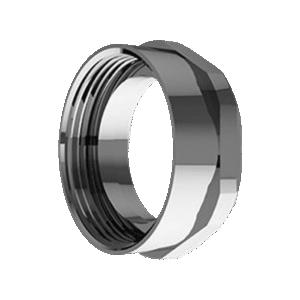

Apollo 70‑104‑27 locking ball valve 3/4″ 600 psi – bronze FNPT two‑piece valve with stainless‑steel latch‑lock lever for safe high‑pressure shutoff.

Apollo 70‑104‑27 locking ball valve 3/4″ 600 psi is a premium-quality bronze ball valve engineered for reliable fluid control in industrial and commercial settings. Designed as part of Apollo’s widely trusted 70‑100 series, this model features a durable cast bronze body, RPTFE seats, and an SS latch‑lock lever that ensures secure shutoff and compliance with lockout/tagout safety protocols.

With a working pressure rating of 600 psi for water/oil/gas and 150 psi for saturated steam, the Apollo 70‑104‑27 locking ball valve 3/4″ 600 psi is optimized for high-demand environments. Its vacuum rating down to 29 in Hg makes it versatile across pressure regimes, while the blow‑out proof stem and corrosion-resistant materials guarantee long-term performance.

Manufactured in Apollo’s South Carolina facility, this valve meets MSS SP‑110 standards and complies with Federal Specification WW‑V‑35C Type II, Style 3. It features a chromium‑plated brass ball and MPTFE stem packing, along with PTFE body seals for excellent chemical compatibility and resistance to wear. The latch‑lock lever is secured by a stainless‑steel nut to prevent unintentional opening.

Lockable SS latch‑lock lever for enhanced safety and compliance

600 psi WOG rating, 150 psi steam capacity

Bronze 2‑piece body with RPTFE seats and chrome‑plated brass ball

Blow‑out proof stem design

Vacuum capable to 29 in Hg

Meets MSS SP‑110 and federal standards

Easy maintenance with standard FNPT threaded connections

| Specification | Value |

|---|---|

| Model / Part Number | Apollo 70‑104‑27 |

| Size | 3/4 in (≈ 19 mm) |

| Pressure Rating (WOG) | 600 psi |

| Steam Rating | 150 psi (saturated steam) |

| Vacuum Capability | 29 in Hg |

| Body Material | Cast Bronze (B584‑C84400) |

| Ball Material | Chrome‑Plated Brass |

| Seat Material | RPTFE |

| Stem Packing | MPTFE |

| Seal Material | PTFE |

| Handle | SS latch‑lock lever with vinyl grip |

| End Connections | 3/4″ FNPT Threaded Inline |

| Port Type | Standard Port |

| Maximum Operating Temp | 450 °F (≈ 232 °C) |

| Minimum Operating Temp | -20 °F (≈ -29 °C) |

| Body Style | Two‑piece ball valve |

| Series | 70‑100 |

| Standards Compliance | MSS SP‑110, WW‑V‑35C |

| Weight | 1.40 lb |

Ideal for:

Industrial and commercial water, oil, gas pipelines

Boiler and steam systems (up to 150 psi)

HVAC and refrigeration setups

Safety-critical environments requiring lockout operations

The Apollo 70‑104‑27 locking ball valve 3/4″ 600 psi ensures secure shutoff and reliable performance in high-pressure and safety-regulated applications.

Wrap PTFE thread sealant tape or apply compatible sealant on male NPT threads only

Hand‑tighten then torque per pipe spec

Latch the lever closed for lockout situations

Inspect seats and seals periodically, especially in high-temperature or cycling service environments

For steam systems, use appropriate insulation and follow thermal expansion guidelines

Industry‑leading 600 psi WOG rating for robust performance

Durable bronze and RPTFE construction

Lock‑out ready with stainless steel latch option

Trusted Apollo manufacturing and strict quality standards

Versatile across multiple industrial sectors: plumbing, HVAC, manufacturing, and utilitie

| Weight | 1.4 kg |

|---|---|

| Dimensions | 3 × 1.5 × 2.12 cm |

Tapes

In stock & ready to ship

Office Supplies

In stock & ready to ship

Fastening

In stock & ready to ship

Belts & Pulleys

In stock & ready to ship

Pneumatic hoses and fittings

In stock & ready to ship

Home

In stock & ready to ship

Personal Protective Equipment

In stock & ready to ship

Plumbing

In stock & ready to ship

Fastening

In stock & ready to ship

Fastening

In stock & ready to ship

Reviews

There are no reviews yet.