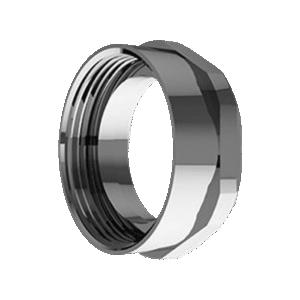

Loctite 620 retaining compound is a high-strength, high-temperature adhesive for bonding cylindrical parts in demanding applications.

Loctite 620 retaining compound is a high-strength adhesive designed to secure cylindrical assemblies exposed to elevated temperatures. Its green color identifies it easily among other LOCTITE products, and its performance in extreme heat (up to 450°F / 232°C) makes it ideal for high-demand industrial, automotive, and mechanical applications.

Whether you’re bonding bushings, bearings, or sleeves, Loctite 620 retaining compound offers unmatched holding power and thermal resistance.

When you need superior performance in high-heat environments, Loctite 620 retaining compound delivers. It fills gaps between metal surfaces and cures to form a rigid, vibration-resistant bond that can withstand intense thermal cycling.

Key advantages:

High temperature resistance: Up to 450°F (232°C)

High strength: Prevents loosening and slippage under load

Gap filling: Handles diametral gaps up to 0.015″ (0.38mm)

Thermal cycling resistance: Maintains bond even with fluctuating temperatures

Prevents fretting and corrosion: Ideal for rotating or press-fit assemblies

This product is widely used in the assembly of press- and slip-fit parts where high strength and temperature tolerance are critical.

Common uses:

Bearing retention in engines and pumps

Sleeves, shafts, and rotors

Automotive transmissions and gearboxes

Electric motors and industrial equipment

Heavy-duty rotating machinery

Loctite 620 retaining compound is frequently used in both OEM and maintenance environments for its consistent and proven performance.

Clean both surfaces with a solvent to remove oil, dirt, or residues.

Apply a uniform layer of Loctite 620 retaining compound to the shaft and/or housing.

Assemble the parts with a slight rotating motion to distribute adhesive evenly.

Allow 10–15 minutes for handling strength; full cure in 24 hours.

Note: Primer (LOCTITE 7649 or 7471) can be used to speed up cure time or for inactive metal surfaces.

The 50ml bottle offers the perfect volume for ongoing operations, whether in a factory floor, automotive shop, or mechanical workshop.

Clean nozzle for controlled dispensing

Enough product for multiple assemblies

Compact and portable packaging

LOCTITE has earned global trust as a top manufacturer of industrial adhesives. Loctite 620 retaining compound is part of a comprehensive product line tailored to meet the demands of professional engineers, mechanics, and technicians.

It meets or exceeds performance expectations in harsh mechanical and thermal environments where failure is not an option.

| Weight | 0.2 kg |

|---|---|

| Dimensions | 4.25 × 1.5 × 1.2 cm |

Tapes

In stock & ready to ship

Office Supplies

In stock & ready to ship

Fastening

In stock & ready to ship

Belts & Pulleys

In stock & ready to ship

Pneumatic hoses and fittings

In stock & ready to ship

Home

In stock & ready to ship

Personal Protective Equipment

In stock & ready to ship

Plumbing

In stock & ready to ship

Fastening

In stock & ready to ship

Fastening

In stock & ready to ship

Reviews

There are no reviews yet.